PRODUCT INFORMATION

Pentair's oil conditioning system helps to ensure lubrication and hydraulic oils stay clean and reliable. It removes contaminants and water, crucial for preventing equipment failures and controlling costs.

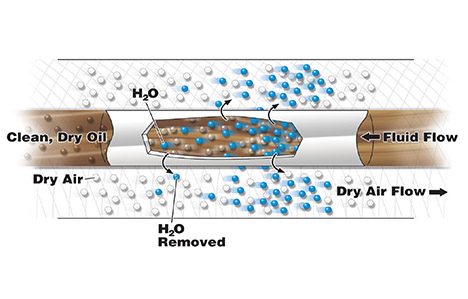

The membrane fiber is bundled into dehydration contactors where the oil to be treated flows through the inside (or Lumen) of the fiber and dry air “sweeps” the outside of the fiber to capture and remove the moisture.

Single contactor Ultidri installed.

Example of a seven contactor Ultidri system.

Ultidri contactor.

- image1

- image2

- image3

- image4

Features

- Helps to minimize equipment wear and improve system reliability

- Prolongs the time between oil changes

- Easy to install, operate and maintain

- Scalable modularity: cost-effective for any application or reservoir size

-

FUNCTIONAL DESCRIPTION

-

Pentair Ultidri System helps to ensure reliable oil conditioning to minimize equipment wear, downtime, and maintenance costs. It's crucial for lubrication systems to maintain a consistent oil layer to reduce friction between moving parts. Water contamination in lubrication and hydraulic systems leads to equipment and lubricant degradation, causing issues like oxidation, additive depletion, viscosity changes, sludge buildup, corrosion, and rust particles.

Pentair Ultidiri System maintains clean and dry fluids continuously, achieving extremely low moisture levels well below saturation limits. This technology combines filtration and membrane techniques to effectively remove contaminants and water from oils. Pentair' Durion Membrane Technology, known for its chemical resistance and durability, plays a key role. By using dry air (<1% humidity), it efficiently extracts free, emulsified, and dissolved water from oils through hollow-fiber membranes. The purified oil remains clean and dry within the system, ensuring optimal performance and longevity.

-

WHAT IT DOES

-

THE ULTIDRI OIL CONDITIONING SYSTEM REMOVE CONTAMINANTS AND WATER FROM LUBRICATION AND HYDRAULIC SYSTEMS

Pentair Ultidri is developed as the ideal alternative to conventional vacuum purifiers, which need highly skilled operators and are generally considered too labor-intensive. Conveniently sized and easy to maintain, the Pentair Ultidri System is well suited for a range of industrial and portable applications. The self-contained units are easy to install, simple to operate, and require only minimal operator intervention.

Providing robust protection in a compact, self-contained package, the portable Pentair Ultidri models are popular because of their versatility and small footprint. A unit may be dedicated to a single reservoir for continuous oil conditioning, or used across multiple reservoirs. With its scalable modularity, allowing for cost-effective application at virtually any flow rate, the Ultidri system offers the ultimate in usage flexibility.

-

APPLICATIONS

-

- Power Generation (Steam Turbines, Wind Turbines)

- Gearboxes

- Industrial Manufacturing (Pulp & Paper, General Manufacturing)

- Mining

- Construction

Filter Dehydrator - ULTIDRI

The ULTIDRI filter-dehydrator has been designed to provide water and particulate removal in a compact, totally self contained, package. Unlike conventional oil purifiers, ULTIDRI has no moving parts, no liquid level controls, no rotating parts, no water drains.

Downloads

| Title | Download PDF |

| UltiDri brochure | Download |