- Home

- applications

- Lubrication and Hydraulics

Effective contamination control has become a critical component of every facility’s maintenance and reliability program. We cost effectively remove contaminants and minimize wear within the system, ensuring reliable service life, predictable operation, and maximum uptime.

Protect against wear, corrosion, fluid breakdown, loss in lubricity, and total failure of the system.

Features

- Design consultation and rapid prototyping services with 3D printing capability

- Build-to-print or standard product modifications

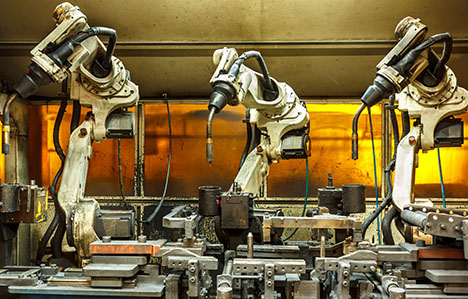

- High speed, automated production for high quality and cost containment

- Wide variety of high quality filter media

- Shorter time to market

- Designed to customer specifications

- High quality, proprietary solutions

-

ABOUT LUBRICATION & HYDRAULICS

-

Lubrication & Hydraulics

Within lubrication and hydraulic systems, contamination, in the form of particulates, moisture and gases, can have significant adverse effects on the operation and service life of the oil and process equipment. They are the primary cause of wear, corrosion, fluid breakdown, loss in lubricity, and in many cases, total failure or seizure of the system.

-

APPLICATIONS

-

Power Generation

A majority of equipment failures can be attributed to contamination. If left unattended, the degradation of additives can expose the sensitive equipment to moisture or result in the formation of varnish and sludge can necessitate extended shutdowns and expensive oil change and system flushing to remove contamination.Industrial Manufacturing

Lubrication systems rely on a layer of oil to separate moving surfaces. Water contamination reduces lubricity and causes the formation of solids within this layer due to the formation of rust, corrosion, varnish deposits, or the breakdown of oils due to oxidation, additive depletion, and changes in viscosity. ULTIDRI® makes extremely low moisture levels attainable – well below the oil saturation limit in most cases.Oil & Gas

The reconditioning of used oil, i.e., oil contaminated with dirt, metals, water, and other chemicals, is essential for the reliable operation of oil and gas operations. While liquid water can be removed from the drum by reservoir settling or coalescing, the UltiDri® system can remove both free and dissolved water from the oil.

BROCHURE

| Title | DOWNLOAD PDF |

| Oil conditioning for lubrication and hydraulic applications. |

Download |

Related products

Clean oil is fundamental to operational reliability. UltiDri is an easily scalable and versatile oil conditioning system to remove solid contaminants and free, emulsified, and dissolved water from lubrication and hydraulic systems.

Stealth ABS (Active Breather System) dehydrates the oil reservoir headspace, eliminating the need to continually replace conventional desiccant breathers, and delivering effortless maintenance.

Developed to protect the lubrication systems in power station turbines, ENVIROSEP can safeguard any industrial lubrication and hydraulic system at risk from varnish formation.

The Ultrafit series filters install into most existing housings without any kits or modifications to the filter. Ultrafit series replacement filter housing for top OEM manufacturers.